产品知识

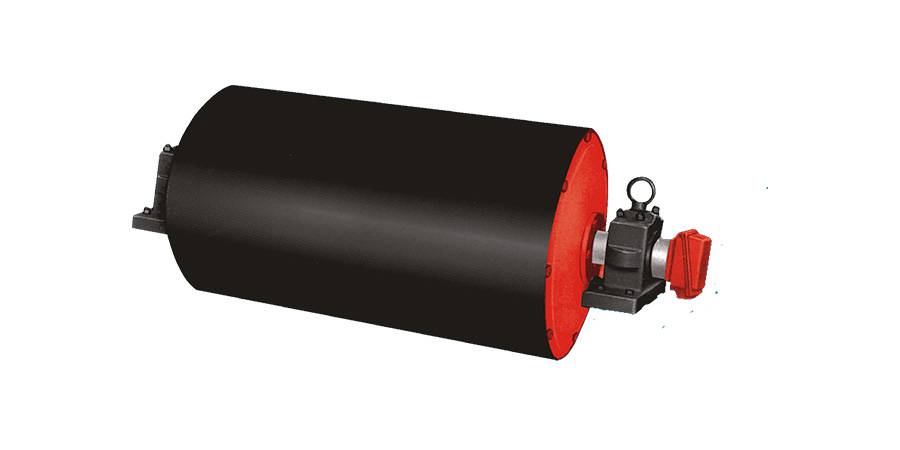

油浸式电动滚筒产品介绍(四)

YD型油浸式电动滚筒是本厂引进国外油浸电动滚筒专有技术设计、消费的目前国内最先进的电动滚筒。该产品电机采用油浸直接冷却,效率高、体积小,与国内同类产品相比,具有重量轻,噪音低、寿命长等优点,已普遍用于电子、食品、邮电、轻工、机场、港口等行业的自动流水线或物料保送线。同时本厂消费各种小型外装式电动滚筒。

YD系列参数选用表:

滚筒直径D | 电机功率P | 滚筒表面线速度 V | 最小筒长 | 系列最小筒长 | 50mm质量 | |

| mm | kw | (m/s) | mm | 长度mm | 质量kg | kg |

| Ø110 | 0.12 | 0.14,0.16,0.20,0.25,0.57,0.63,0.80 | 310 | 350 | 12 | 0.8 |

| 0.25 | 0.04,0.047.0.05.0.055.0.06.0.065.0.07.0.075.0.08 .0.09.0.10.0.12.0.152.0.20 | 350 | 350 | 16 | 1.1 | |

| 0.25,0.30,0.32,0.34.0.38.0.44.0.53 | 320 | 350 | ||||

| Ø130 | 0.25 | 0.046,0.056,0.065,0.07,0.08,0.10,0.13.0.15.0.18.0.226 | 350 | 350 | 17 | 1.5 |

| 0.29.0.35.0.40.0.45.0.52.0.63 | 320 | 350 | ||||

| 0.55 | 0.046,0.056,0.058.0.068.0.071.0.08.0.09.0.10.0.12.0.14 | 400 | 400 | 19 | 1.5 | |

| 0.29.0.35.0.40.0.45.0.52.0.63 | 370 | 400 | ||||

| Ø174 | 0.75 | 0.03.0.04.0.05.0.063.0.08.0.10.0.13.0.16.0.20 | 470 | 500 | 50 | 2.3 |

0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60.2.00 | 400 | 400 | 40 | |||

| Ø216 | 0.75 | 0.05.0.063.0.08.0.10.0.13.0.16.0.20.0.25 | 470 | 500 | 70 | 3.0 |

0.32.0.40.0.50.063.0.80.1.00.1.25.1.60.2.00.2.50 | 400 | 400 | 60 | |||

| 1.1 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00 | 410 | 450 | 63 | ||

1.5/2.2 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00 | 460 | 500 | 69 | ||

| 3 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00 | 510 | 550 | 73 | ||

| Ø240 | 0.75 | 0.056.0.07.0.089.0.11.0.14.0.18.0.22.0.28.0.36 | 470 | 500 | 80 | 3.3 |

0.44.0.56.0.70.0.89.1.11.1.39.1.78.2.22.2.78 | 400 | 400 | 70 | |||

| 1.1 | 0.14.0.18.0.22.0.28.0.36.0.44.0.56.0.70.0.89.1.11.1.39 | 410 | 450 | 70 | ||

1.5/2.2 | 0.14.0.18.0.22.0.28.0.36.0.44.0.56.0.70.0.89.1.11.1.39 | 460 | 500 | 78 | ||

| 3 | 0.14.0.18.0.22.0.28.0.36.0.44.0.56.0.70.0.89.1.11.1.39 | 510 | 550 | 81 | ||

| Ø320 | 1.1 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25 | 420 | 450 | 120 | 3.7 |

1.5/2.2 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25 | 470 | 500 | 126 | ||

| 3 | 0.13.0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25 | 520 | 550 | 132 | ||

4 | 0.25,0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60.2.00.2.50 3.15 | 560 | 600 | 150 | ||

| 5.5 | 0.25,0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60.2.00.2.50 3.15 | 560 | 600 | 155 | ||

| 7.5 | 0.50.0.63.0.80.1.00.1.25.1.60.2.00.2.50.3.15 | 660 | 700 | 160 | ||

| Ø400 | 1.1 | 0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60 | 420 | 450 | 140 | 5.5 |

1.5/2.2 | 0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60 | 470 | 500 | 145 | ||

| 3 | 0.16.0.20.0.25.0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60 | 520 | 600 | 152 | ||

| 4 | 0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60.2.00.2.50.3.15 | 560 | 550 | 170 | ||

| 5 | 0.32.0.40.0.50.0.63.0.80.1.00.1.25.1.60.2.00.2.50.3.15 | 560 | 650 | 175 | ||

| 7.5 | 0.63,0.80.1.00.1.25.1.60.2.00.2.50.3.15.4.00 | 660 | 750 | 190 | ||

| ·安装及外形尺寸 |

|

| 注:安装中心距A=L+2f+c。 带支座时,A为两支座中心距离;不带支座时,A为两端轴头铣扁的中心距离。 |

滚筒直径D(mm) | a | b | c | d | e | f | g | h | s |

Ø110 | / | / | 20 | 25 | 21 | 5 | / | / | / |

| Ø130 | / | / | 20 | 25 | 21 | 5 | / | / | / |

| Ø174 | 120 | 160 | 60 | 32 | 25 | 5 | 105 | 50 | 15 |

| Ø216 | 120 | 160 | 60 | 38 | 30 | 5 | 105 | 50 | 15 |

Ø240 | 120 | 160 | 60 | 38 | 30 | 5 | 105 | 50 | 15 |

| Ø320 | 210 | 260 | 60 | 42 | 35 | 10 | 120 | 95 | 19 |

| Ø400 | 210 | 260 | 60 | 42 | 35 | 10 | 120 | 95 | 19 |

| 注:0.75kw的φ216、φ240的滚筒的安装与φ174滚筒的安装尺寸相同。 |