产品知识

TJ型电动滚筒的功率多大?

2018-09-26

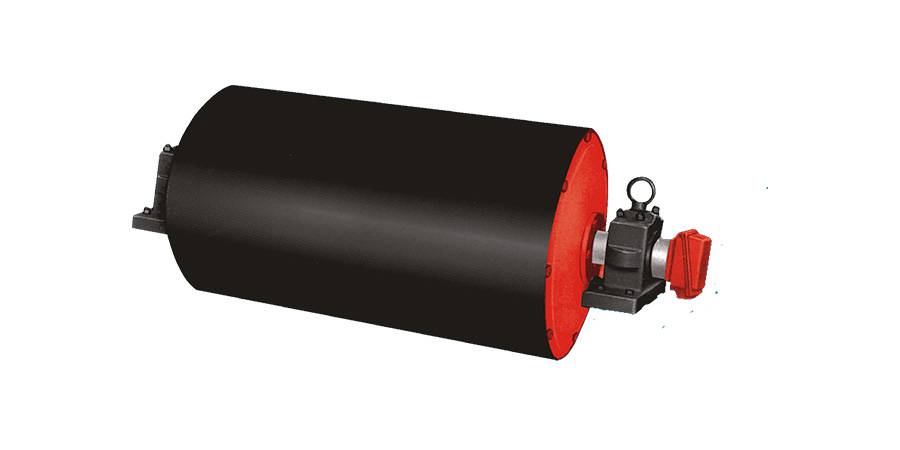

TJ型电动滚筒的功率、速度、直径、筒宽均契合ISO规范和IEC规范,通常配KL型支座可适用于国内外各种皮带运输机、料斗提升机等保送设备。为了便当用户,我们设计了TZ型支座,其装置尺寸与TD75型皮带运输机完整相同。

电动滚筒作为独立的闭式驱动组件,还能够作为动力式辊子保送机、卷扬机等设备的动力源。电动滚筒与普通开式减速机相比,具有构造紧凑、重量轻、占领空间小、密封性好、外形美观、装置便当、维修简单等优点。普遍遭到广阔用户的欢送。

采用TJ型电动滚筒,按下列公式计算,所需求电动滚筒的电机功率。

功率的计算,在各种机械手册中都有引荐公式,但方式不尽相同,计算结果也可能稍有出入。为了使电动滚筒的设计计算与用户的运用请求统一同来,我们引荐采用下列公式计算电动滚筒所需求的功率:

式中:P—电动滚筒的轴功率(KW)

C—保送带、轴承等处的阻力系数,数值能够从表1中查到。

f—托辊的阻力系数f=0.025~0.030

L—保送机的电动滚筒与改向滚筒之间中心距的程度投影(m)

Gm—保送带、托辊、改向滚筒等旋转零件的重量,数值可从表2中查到。(kg/m)

V—带速(m/s)

Qt—保送量(t/h)

H—保送高度(m)

B—带宽(mm)

TJ type electric drum power, speed, diameter, tube width and fit the ISO specification and IEC specification, usually with KL support can be applied to domestic and foreign various belt conveyers, hopper lifting machine walks. For the convenience of users, we designed TZ type bearing, the device size and complete the same TD75 type belt conveyor.

Electric roller as driving component closed type independent, but also can be used as a power source of the power type roller conveyor, hoist equipment. Electric drum compared with ordinary open reducer, with compact structure, light weight, small occupied space, has the advantages of good sealing performance, beautiful appearance, convenient installation, simple repair etc.. Generally by the user's welcome.

Using TJ type electric drum, according to the following formula, motor power demand electric drum.

Power calculation, have recommended formula in various mechanical manual, but not the same, the calculation results also may be a slight discrepancy. In order to apply the design calculation and the user electric drum of the request of the same power to, we recommend using the following formula of electric drum needs:

In the formula: P - electric drum shaft power (KW)

Drag coefficient C conveyor belt, bearing, values from table 1 to check.

Drag coefficient f=0.025~0.030 f roller

Electric drum L conveyor and improve the degree of projection to the drum center distance (m) between

Gm conveyor belt, roller, direction change drum rotating parts weight values can be found in table 2. (kg/m)

V - belt speed (m/s)

Qt recommended weight (t/h)

H recommended height (m)

B bandwidth (mm)

Electric roller as driving component closed type independent, but also can be used as a power source of the power type roller conveyor, hoist equipment. Electric drum compared with ordinary open reducer, with compact structure, light weight, small occupied space, has the advantages of good sealing performance, beautiful appearance, convenient installation, simple repair etc.. Generally by the user's welcome.

Using TJ type electric drum, according to the following formula, motor power demand electric drum.

Power calculation, have recommended formula in various mechanical manual, but not the same, the calculation results also may be a slight discrepancy. In order to apply the design calculation and the user electric drum of the request of the same power to, we recommend using the following formula of electric drum needs:

In the formula: P - electric drum shaft power (KW)

Drag coefficient C conveyor belt, bearing, values from table 1 to check.

Drag coefficient f=0.025~0.030 f roller

Electric drum L conveyor and improve the degree of projection to the drum center distance (m) between

Gm conveyor belt, roller, direction change drum rotating parts weight values can be found in table 2. (kg/m)

V - belt speed (m/s)

Qt recommended weight (t/h)

H recommended height (m)

B bandwidth (mm)

表1

L(m) | 3 | 4 | 5 | 6 | 8 | 9 | 10 | 16 | 20 |

C | 9.0 | 7.6 | 6.6 | 5.9 | 5.1 | 4.5 | 4.1 | 3.6 | 3.2 |

L(m) | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 |

C | 2.9 | 2.6 | 2.4 | 2.2 | 2.0 | 1.9 | 1.8 | 1.65 | 1.59 |

L(m) | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

C | 1.47 | 1.38 | 1.33 | 1.35 | 1.20 | 1.17 | 1.13 | 1.11 | 1.08 |

表2

B(mm) | 500 | 600 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | |

Gm | 标准输送带 | 17 | 26 | 28 | 40 | 56 | 70 | 85 | 105 | 120 |

重载输送带 | 20 | 30 | 32 | 45 | 62.5 | 80 | 110 | 135 | 160 | |

最新资讯